Rockwell Hardness Chart For Metals

818.

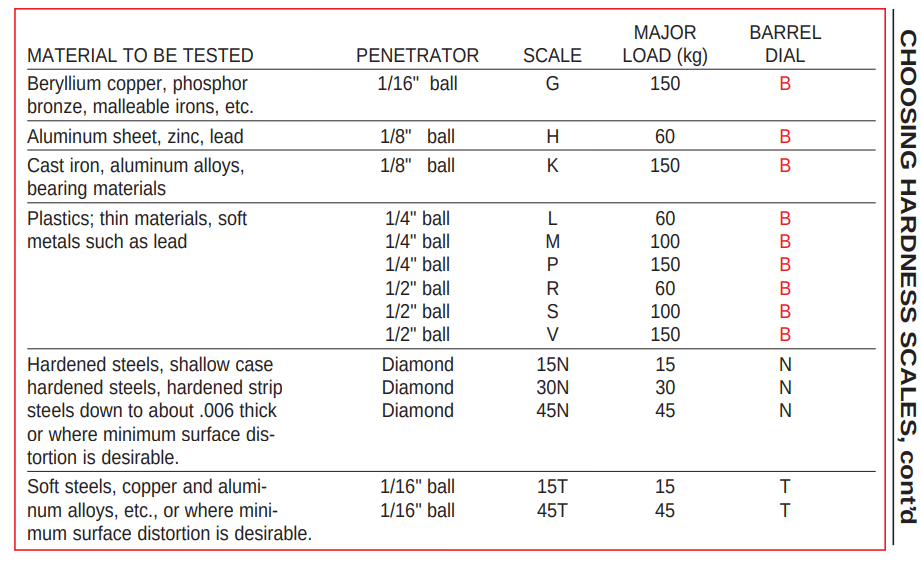

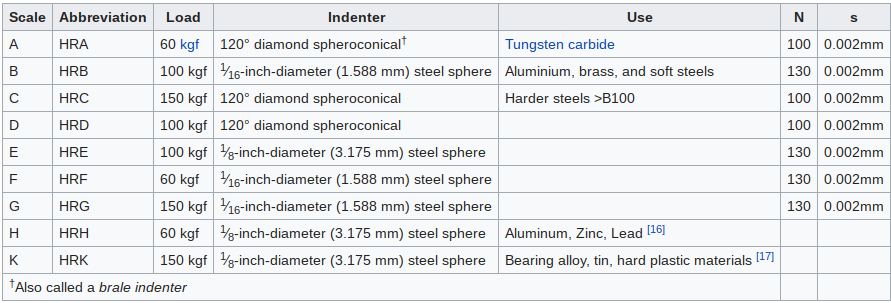

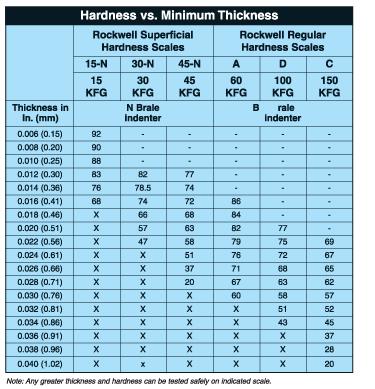

Rockwell hardness chart for metals. Steel hardness conversion chart - all values approximate. Machinability of CD1212. Sheet metal as thin as 0006 inch can be tested on the Rockwell.

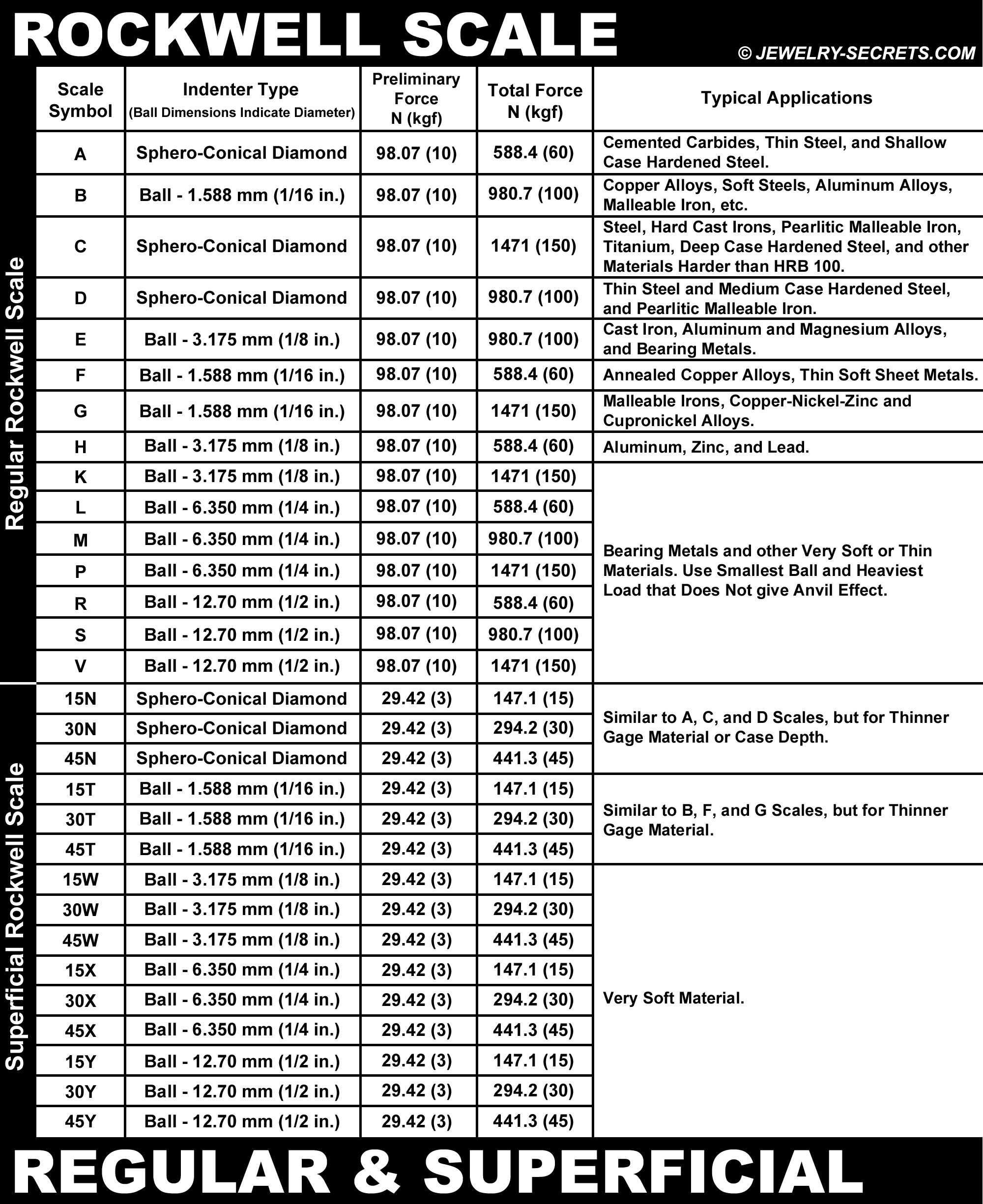

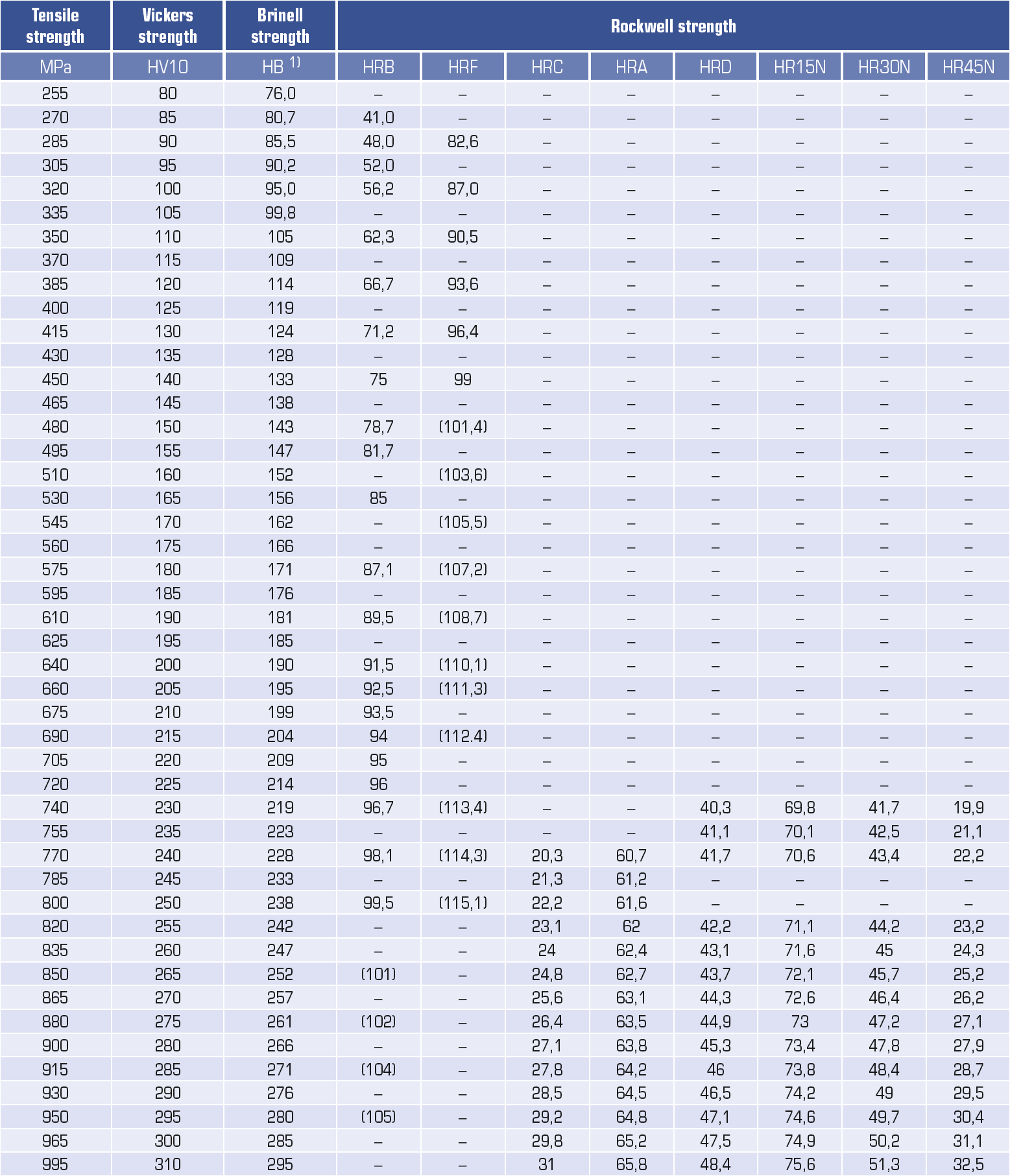

ROCKWELL HARDNESS TESTING 17 6. 823 670 61. For example HRC 96 for a metal means the hardness of that metal is 96 when measured using.

The higher the number on the RC scale the harder the steel is. Most Rockwell hardness numbers are presented to the nearest 01 or 05 hardness number to permit accurate reproduction of these curves. HARDNESS VS MINIMUM THICKNESS CHART 55.

The below chart is useful for determining which metals will be impervious to scratching and dinging as it relates to the Rockwell scale and ductility. Brinell Hardness Rockwell B Scale Rockwell C Scale Vickers Hardness Number Knoop Hardness Rockwell A Scale Rockwell F Scale 15T Scale 30T Scale 45T Scale Approximate Tensile Strength. 150 - 200 190 - 220 320 415 352.

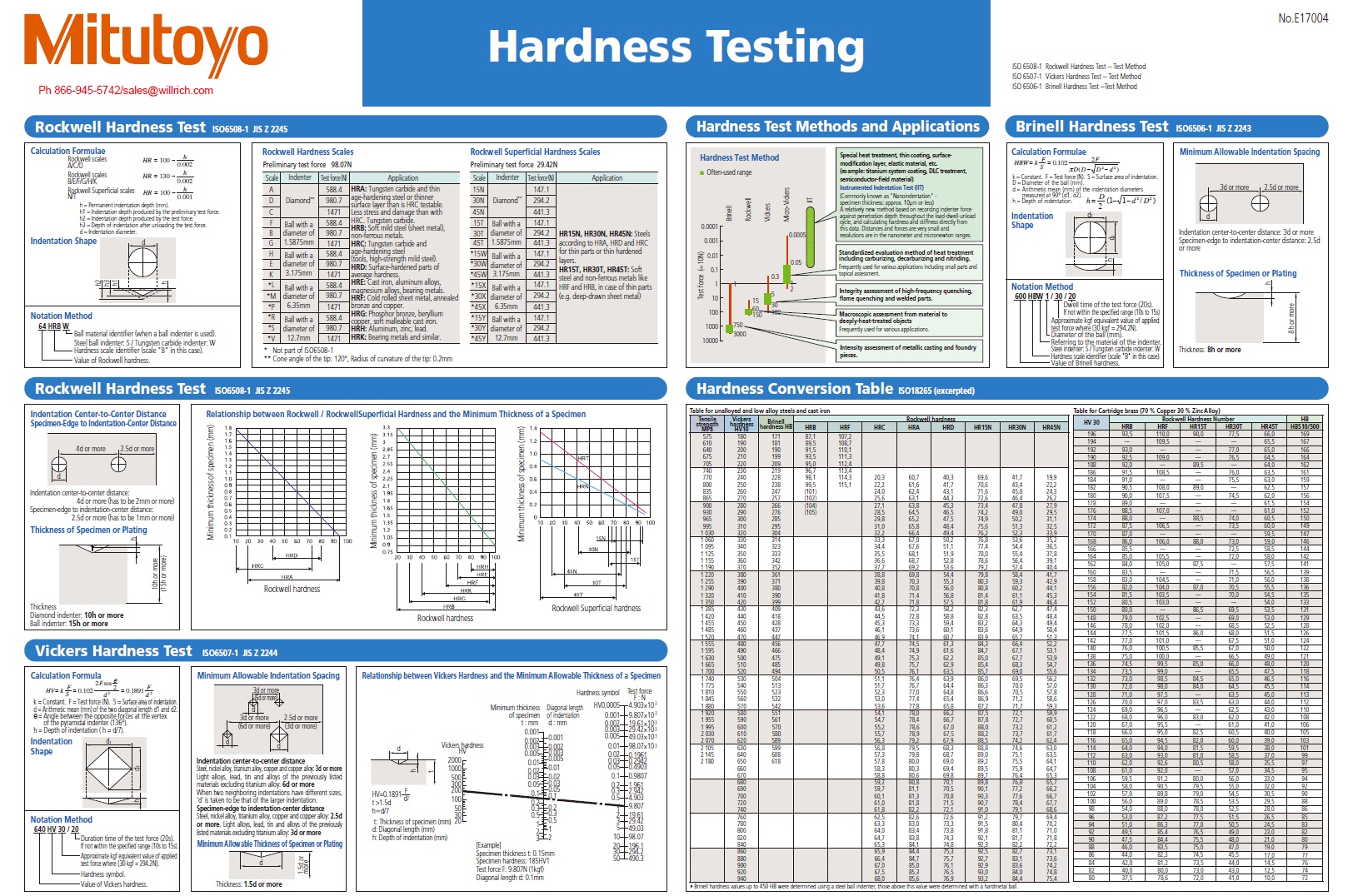

313 Rockwell hardness testan indentation hardness test. PRACTICAL HARDNESS TESTING MADE SIMPLE 1 1. In the knife blade manufacturing business hardness ratings follow a predetermined chart which is commonly called the Rockwell C scale.

828 688 62. The Rockwell scale is a hardness scale based on indentation hardness of a material. Of austenitic stainless steel sheet.

834 706 63. 17 Conversion Table 7 presents data on the relationship among Brinell hardness Vickers hardness Rockwell hardness Rockwell superficial hardness and Knoop hardness of copper. 72 HRBW Rockwell hardness number of 72 on the Rockwell B scale measured using a tungsten carbide ball indenter.

The Rockwell Hardness Chart for Metals is a chart that has been used extensively in the. This booklet intends to stress the significance of. Standard Hardness Conversion Tables for Metals for information on where to find see at the end of this publication is the.

80 - 90B 83 - 95B 80 - 90B 80 - 90B 80 - 90B 90 - 95B 35C 44C 38C. 150 - 180 160 - 180 150 - 180 150 - 180. 839 722 64.

Conversely the lower the RC scale number is the softer the steel. 18 rows 212000 AR 400 Steel 74 115 46 60 - - - - 84 65 50 - - 432 - - 62 212000 200000 73 114 44 59 - -. The Rockwell test is applicable to a wide range of part sizes.

3123 Examples64 HRC Rockwell hardness number of 64 on Rockwell C scale. Rockwell Superficial Hardnes sScales Regular Hardnes Scales Any greater thickness and hardness can be safely tested on indicated scale Thickness inches mm N Brale Indenter Brale Indenter 006 015 008 020 010 025 012 030 014 036 016 041 018 046 020 051 022 056 024 061. Tensile Strength Nmm2 Brinell Hardness BHN Vickers Hardness HV Rockwell Hardness HRB Rockwell Hardness HRC 285.

81 HR30N Rockwell superficial hardness number of 81 on Rockwell 30N scale. 20 rows Steel C Scale 150 kgf D Scale 100 kgf A Scale 60 kgf 15N Scale 15 kgf 30N Scale 30 kgf 45N Scale. Metal Hardness Chart.